Address: No. 188, Xin Zhan North Road, Zhangjiagang, Jiangsu

Contact: Mr. Cao

Cell phone: 13806227123

Phone: 0512-58968100

Fax: 0512-58968100

Zip code: 215600

E-mail:1197414559@qq.com

Web site: www.zjgzykj.com

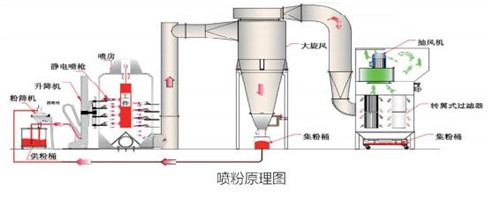

Powder spraying equipment includes powder room, powder supply system (Gun + hoist), recovery device, ventilation system, etc., the recovery device has cloth bag + cyclone, filter core, small whirlwind + filter bag, small whirlwind + porous board and other forms.

The dry powder is loaded into the powder flow after simply conveying compressed air to the spray gun, spray gun in according to the principle of voltage doubling by 10V to produce a high voltage low voltage, using multi electrode powder with 70 to 1 million volts in flight, using the spray gun and workpiece grounding electric field is formed between the powder into the the power line of the workpiece, and with a total surplus electricity and adsorbed on the workpiece.

Powder spraying equipment, spraying equipment is mainly divided into two categories:

1., manual dusting equipment;

2. automatic powder spraying equipment

The principle of manual spraying: (with activity, low cost of investment)

In the powder room on both sides of the oblique relative with two stations, the operator is standing at the station, the workpiece by hanging empty chain drive, when the workpiece through the station, the job of the surface of the product dusting processing, so continuous operation

The principle of automatic spraying: (unity, efficiency, cost of investment)

The upper and lower reciprocating reciprocating machines are arranged on both sides of the powder room, and a powder spray gun is arranged on the reciprocating machine, and the workpiece is driven by an air lifting chain, and the powder is sprayed when the workpiece passes through the spray gun

Powder cabinet production instructions:

Dusting cabinet adopting iron tube or stainless steel pipe production, adjustable feet cup box made of galvanized steel or stainless steel plate bending production, recycling used filter blowback with centrifugal fan or a centrifugal cyclone recovery, recycling barrel bottom is provided with casters, to facilitate the collection of recycling powder, using 40W explosion-proof lamp lighting control, the use of intermittent play using high-quality brand electrical electrical powder.

Powder recovery principle:

The powder room by recycling fan powder containing air attraction, followed by.99.5% of the powder separator filter in the filter is separated into a powder bucket, by Venturi conveyed to the automatic gun for powder barrels used repeatedly. In order to ensure the ability to filter through the filter, filter recovery device for adjustable pulse, with compressed air blowing device, adjustable interval from the filter cleaning from the inside out, as the filter impulse from the inside to the outside, the effect of compressed air expansion powder, cleaning filter continuously effectively, so as to ensure the recovery effect of the filter element.