Address: No. 188, Xin Zhan North Road, Zhangjiagang, Jiangsu

Contact: Mr. Cao

Cell phone: 13806227123

Phone: 0512-58968100

Fax: 0512-58968100

Zip code: 215600

E-mail:1197414559@qq.com

Web site: www.zjgzykj.com

Washing tower device

![]()

A, all kinds of harmful gases, such as benzene, toluene, xylene, H2S, SOX, NOX, HCL and other gas treatment;

B,The deodorization device of sewage treatment plant, waste transfer station, sludge treatment yard and food waste disposal field;

C, semiconductor optoelectronic industry process exhaust treatment;

D, landfill waste water storage pond waste gas treatment;

E, electroplating factory (electroplating, acid washing, immersion plating operation) waste gas treatment;

F, spray paint room, printed circuit board factory waste gas treatment;

G, printing machinery plant oil mist waste gas treatment and so on

![]()

The scrubbing tower is a two phase reverse flow packing absorber. The gas enters the purification tower along the tangential direction from the gas inlet below the tower body. Under the dynamic action of the fan, it quickly fills the intake section space and then rises evenly through the current sharing section to the first stage packing absorption section. On the surface of the filler, there is a chemical reaction between the contaminants in the gas phase and the substance in the liquid phase. The reactant (mostly soluble salts) with the absorption liquid flows into the lower reservoir. The gas that is not fully absorbed continues to rise into the spray section. In the spray section, the absorption liquid is spewed out at high speed from the uniform nozzle, forming numerous fine droplets and gas to be fully mixed, contact and continue to react. The process of two phase contact in the spray section and the filling section is also the process of heat and mass transfer. The full and stable process is ensured by controlling the flow velocity and storage time of the air tower. The exhaust gas is from the tower body (reverse flow) to reach the gas and liquid contact. This treatment can cool exhaust gas, remove particles and purify gas. The uppermost part of the tower is the demister section. The droplets of the absorption liquid entrained in the gas are removed here, and the cleaned air after treatment is discharged into the atmosphere from the upper end of the washing tower.

![]()

System composition

The main a and PH control device for the main body of the A washing tower

B and ORP control device for the spray system of B washing tower

C filling material C, drug storage tank

D water mist remover D and drug level control device

E inspection window, maintenance entry

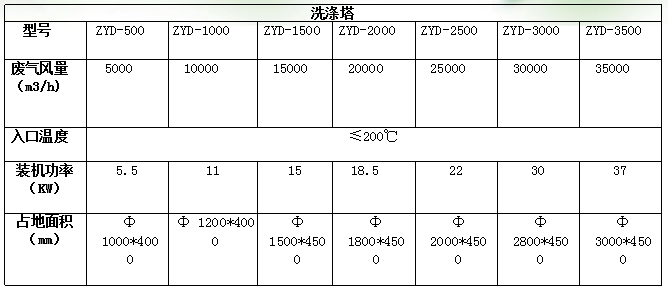

Type of washing tower

A, organic washing tower (removal of organic waste gas);

B, acid and alkali waste gas washing tower (removal of acid and alkali gas, etc.);

C, hot exhaust (removal of steam, hot air, etc.);

D, wet absorption tower (removal of particles.